CiES FUEL SENDER

GENERAL INSTALLATION INSTRUCTIONS

Here you can find general installation instructions for CiES fuel senders. An index is provided here.

You may also choose to download the instructions, and may do so below. If you need specialized instructions for Cessna Twin, Cirrus or Piper PA46, you can find them in the right sidebar.

Here you can find general installation instructions for CiES fuel senders. An index is provided here.

You may also choose to download the instructions, and may do so below. If you need specialized instructions for Cessna Twin, Cirrus or Piper PA46, you can find them here.

click any file below to view and download the document

1. Introduction

This document provides the FAA-approved installation instructions for the installation of CiES fuel tank level sending units in accordance with STC SA02511SE on eligible aircraft models.

CiES CC-Series fuel senders are TSO certified to C55a and associated SAE AS405C.

They have met all the FAA Environmental Requirements & Complex Programmable Hardware Requirements for general aviation aircraft and the TSO.

CiES Fuel Senders are patented, and patent pending technology and are not offered by any other manufacturer.

CiES Fuel Senders operate on a different principle than traditional float senders and are designed specifically for aircraft applications. CiES fuel senders measure the direction of a generated magnetic field direction at the pivot point of the float arm rotor assembly. Internal inside the body of the sender and outside the fuel, is a high precision electronic compass that is sensitive to the magnetic field direction. It is essentially a compass that points to north – only in this case north is the fuel float.

By disconnecting the float and float arm from the electronics or any mechanical system, the float is free to find the fuel surface without any encumbrance to movement up or down. CiES then utilizes a denser float to achieve a measure of damping as the float does not need to be sized to overcome friction.

By measuring magnetic field, precision is maintained throughout the life of the sender as mechanical slop, vibration or misalignment have no bearing on the accuracy of measurement. This is a difficult concept to understand, but basically no matter how you jostle an electronic compass – North is always North.

2. Approved Configurations

The combination of the CiES fuel sender part numbers and indicators approved on each applicable airplane model are listed in the AML tables of STC SA02511SE

3. General Specifications

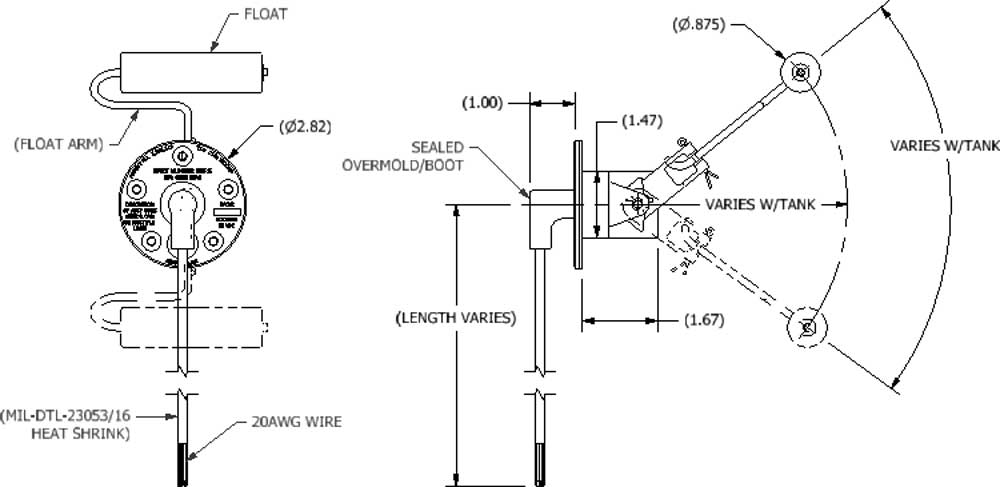

3.1 Physical Dimensions

Floats, arm lengths, and travel angles vary depending on Aircraft application.

Some PMA parts utilized for aircraft fuel tanks have patterns that are not identical to the OEM factory produced components. Contact CiES, Inc. if PMA parts do not allow for correct installation of the new sender.

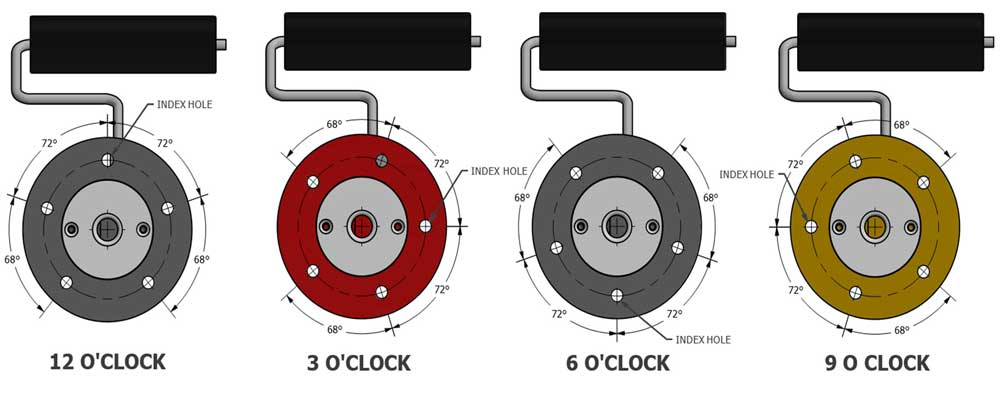

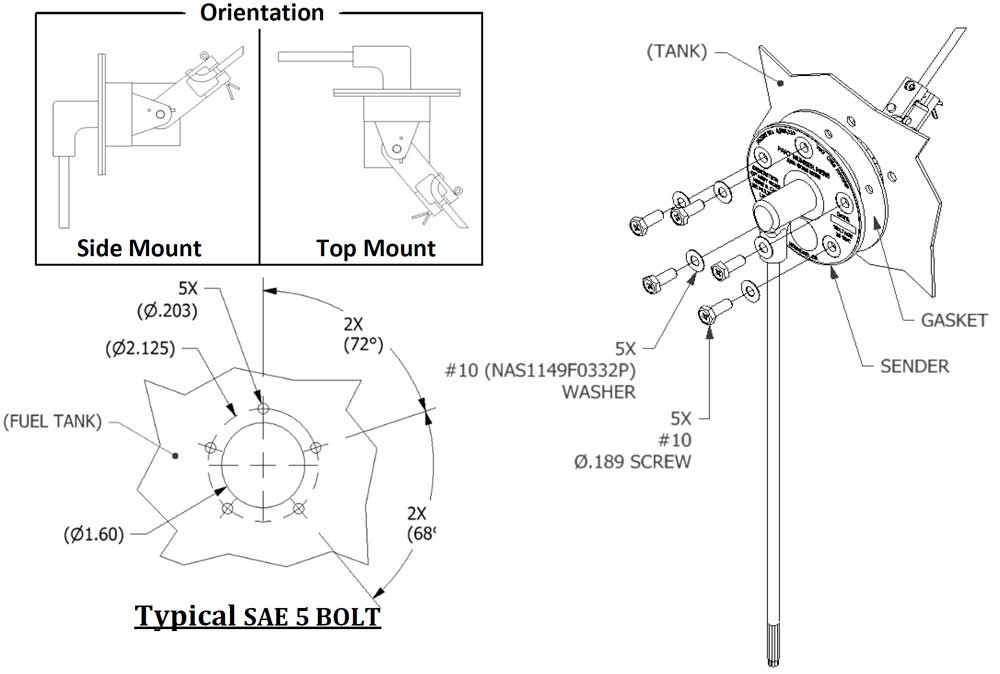

3.2 Mounting & Installation

3.3 Mounting & Installation

CiES Fuel Senders due to the patented sensor system allow for more angular travel than a traditional resistance sender. This travel range is a distinct advantage that makes CiES systems simpler to construct and install. However:

4. Electrical Installation

4.1 Operating Voltage

Operating Voltage Range |

|

|---|---|

| Voltage “VDC” | 9 ‐ 28 |

4.2 Power Consumption

Voltage “VDC” | Steady State Current “mA” |

|---|---|

14 | 17.1 |

28 | 9.6 |

4.3 Signal Output Range(s)

| Output Type | Signal | Range | Output Range |

|---|---|---|---|

TEMPERATURE | Output to be the following: |

||

| Option 1 | 0-5 Vdc Square Wave | -50°C to 50°C -58°F to 122°F | FREQ 1,200Hz - 490Hz |

FUEL LEVEL | Output to be the following: |

||

| Option 2 Frequency | 0-5 Vdc Square Wave | 5° - 175° Angular Travel | FREQ 16,384Hz - 64Hz |

| Option 3 Resistance (Not Common - Typically a Voltage Unit) | Resistance 0 - 280 Ohm | 5° - 175° Angular Travel | Resistance 0 - 280 Ohm |

| Option 4 Voltage | Voltage 0 - 5 Vdc | 5° - 175° Angular Travel | Voltage 0 - 5 Vdc |

4.4 Wire Color Designations

| WIRE DESIGNATIONS | ||

|---|---|---|

| Wire Color | Designation | CiES Fuel Sender Type |

| Red | Power | All CC284022 (XXXX)-(XXX) |

| Black | Ground | All CC284022 (XXXX)-(XXX) |

| Blue | Fuel Qty “OUT” in Hz | All CC284022 (XXXX)-(XXX) |

| Orange | Temp. “OUT” In Hz (Option) Or Low Fuel Annunciation | (Special Application only - Contact CiES) |

| Orange/Red | Fuel Qty “IN” Hz (Master/Slave) | CC284022 (XXXX)-(XXX) Master |

| Gray | Fuel Qty “IN” Hz (Master/Slave) | CC284022 (XXXX)-(XXX) Master |

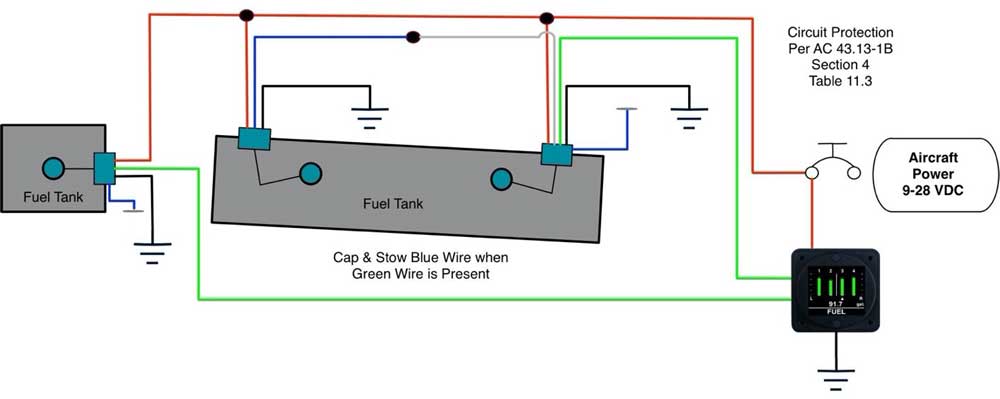

| Green | Fuel Qty “OUT” (0‐5V) | CC284022 (XXXX)-(XX5) or (5XX) Only CC284022-(XXXX)-(XX6) & (7XX) Only |

| Purple (Not Typical, as most Resistive senders are replaced with the Green or voltage output) | Fuel Qty “OUT” (0‐280 ohms) | (Special Application only - Contact CiES) CC284022 (XXXX)-(XX3) or 3XX Only CC284022-(XXXX)-(XX4) Only |

- Wiring: 20 & 22 AWG wires ‐ M22759/11‐20‐X, M22759/16‐20‐X or M22759/16‐22‐X

Heat Shrink ‐ MIL‐DTL‐23053/16 - High performance elastomer Heat Shrink Boot with self‐sealing adhesive, MS25171‐1S Nipple, or

- Heat Shrink MIL‐DTL‐23053/16

4.5 Connectors

CiES Inc. senders are not supplied with connectors unless specifically requested and purchased by customer. Reference each individual assembly for clarification, connector specifications, and/or pin assignments.

5. Electric Installation

CiES Inc. fuel quantity senders operate in a different manner than traditional resistive float senders even though they bare a slight resemblance.

As the power consumption is very low for CiES senders, you may provide less current than the recommendations in the Advisory Circular for 20 or 22 gauge wiring typically 1 to 2 Amps is sufficient. You will have to add the number of CiES senders installed in the aircraft to get a reasonable value of inflight current consumption.

Follow the existing fuel sender signal wire routing for new power wire or new power wire and signal wire in the aircraft, ensure that lacing, wire ty wrap and wire support are maintained in the existing wire bundle.

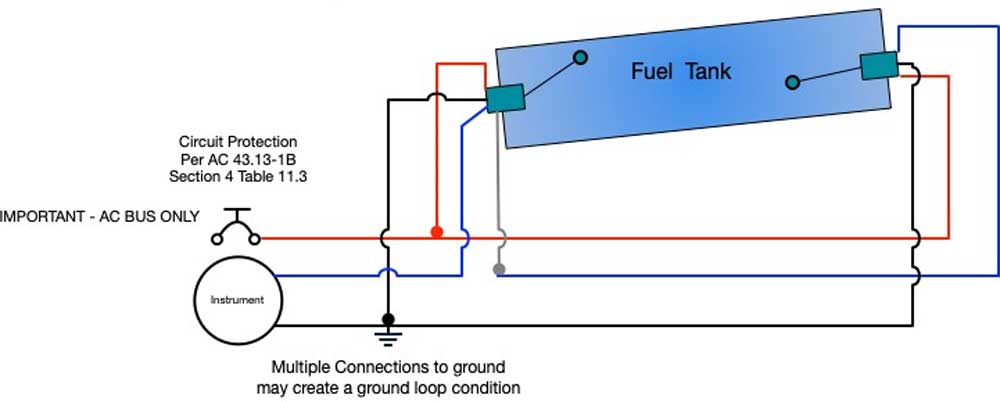

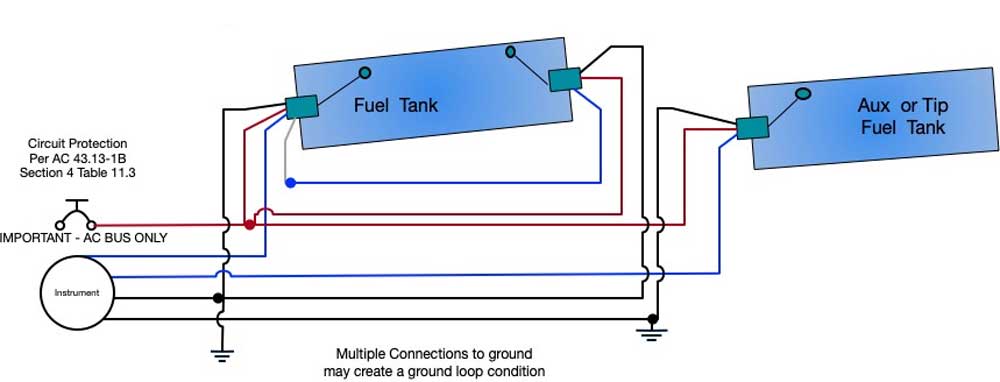

In tanks where two or more sensors are required, the most inboard sensor is the master, and the other senders are slaves. Slaves communicate with the master sender in digital or frequency mode only.

In a single sender tank configuration, the sender is the master.

Master sender output is a choice of digital or analog.

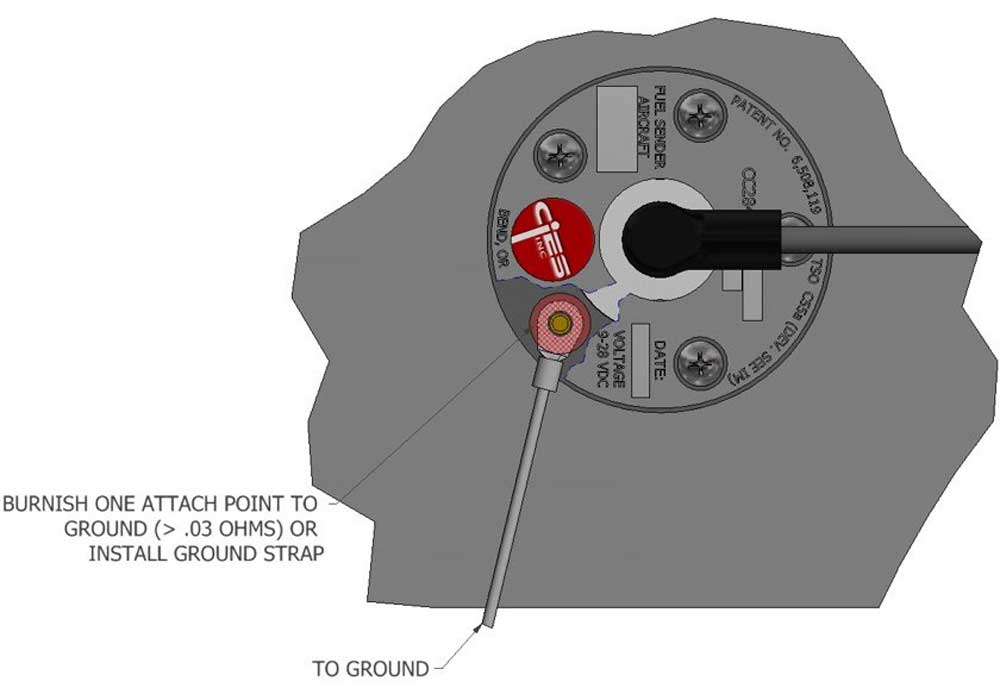

5.1 Bonding (Metal and Metal Tank Aircraft Only)

CiES Inc. fuel quantity senders that are installed in a metal aircraft or in a metal tank must be bonded to the aircraft structure in one of two methods:

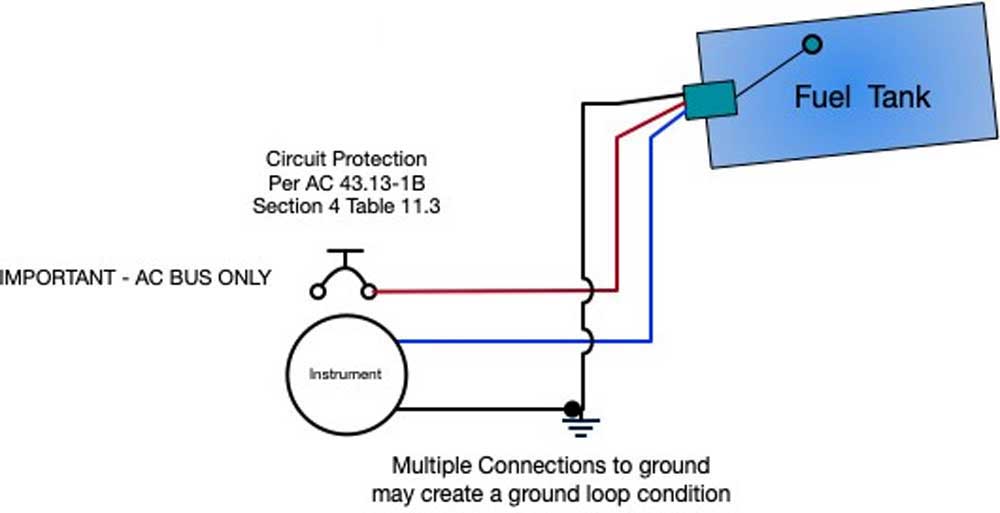

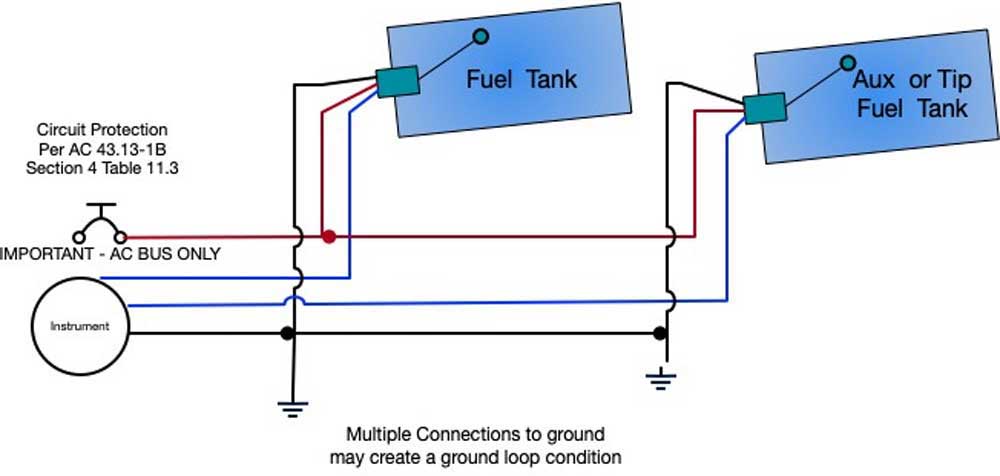

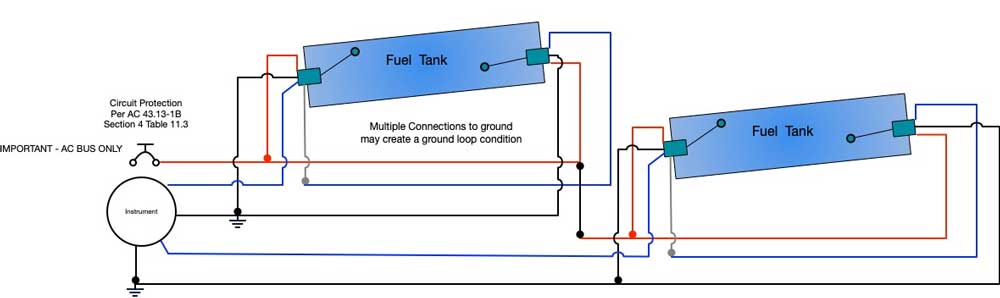

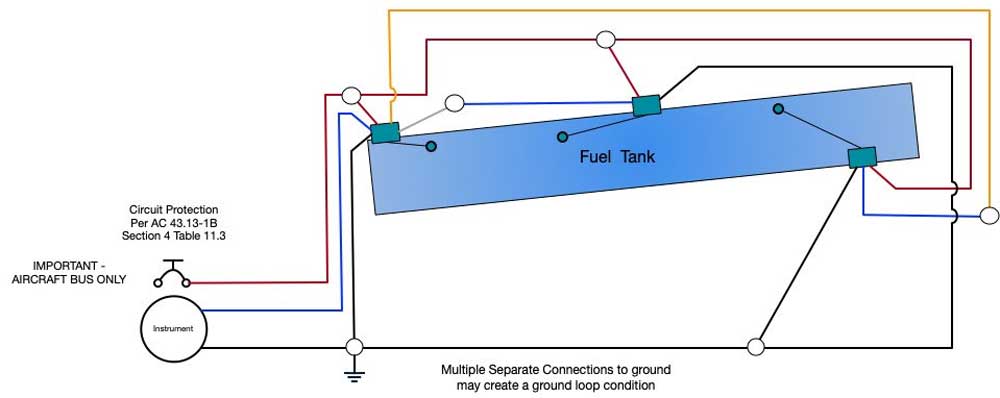

5.2 Generic Installation Schematics - Digital Output

5.2.1 Single Sender Output

5.2.2 Single Sender with Aux Output

5.2.3 Dual Sender Output

5.2.4 Dual Sender with Aux Output

5.2.5 Dual Sender with Dual Aux Output

5.2.5 Triple Sender Output

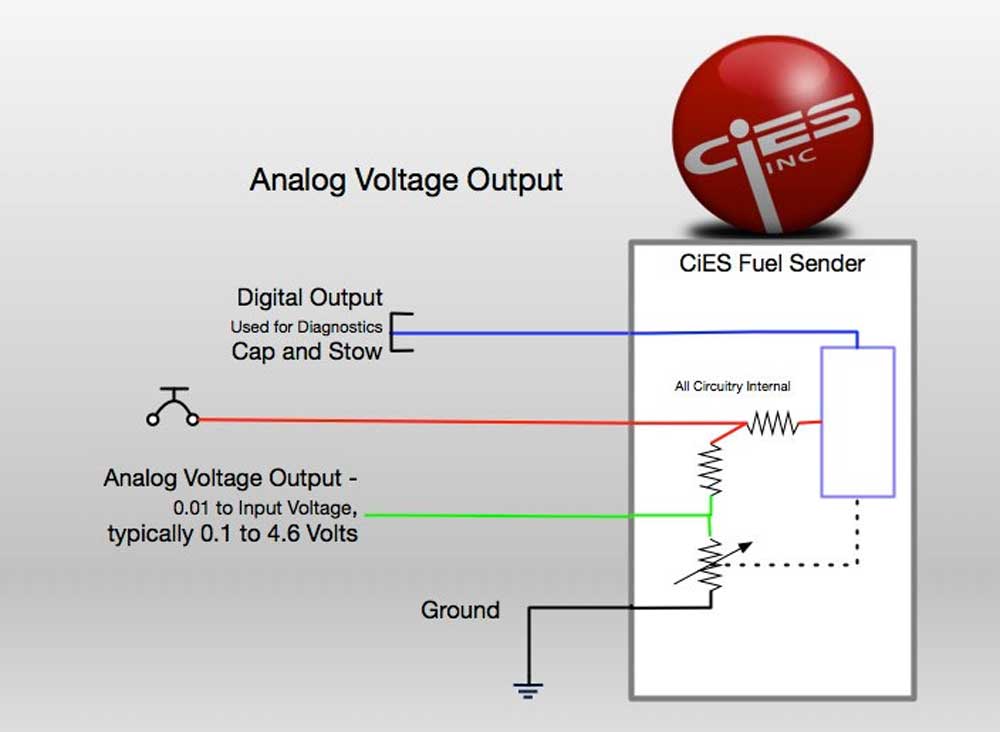

5.3 Analog Voltage Output

For an analog output, the fuel sender operates similarly to a variable resistor to ground in analog voltage mode and will create a 0.1 to 4.7-volt output.

5.3.2 Dual Sender Main and Aux Tank - Analog

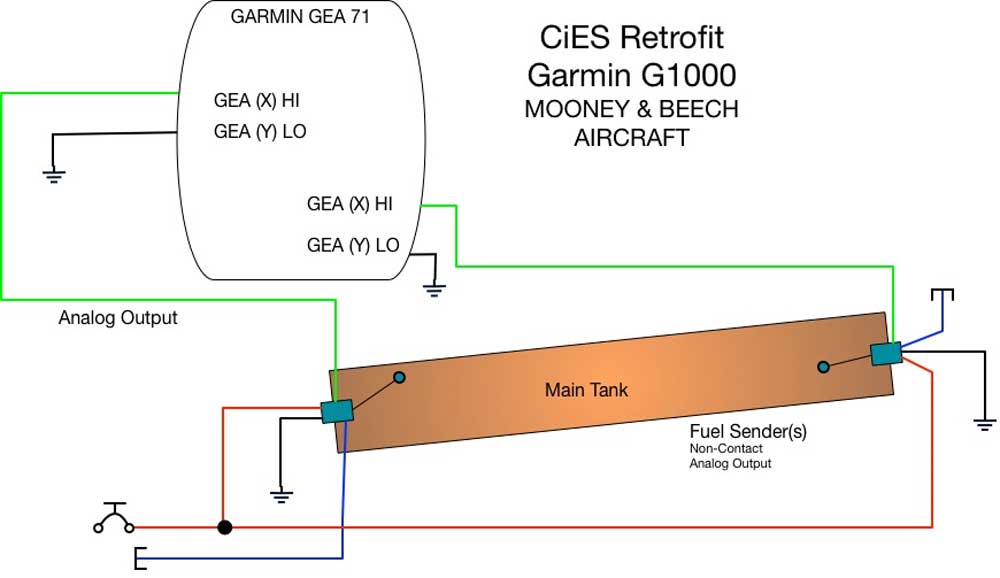

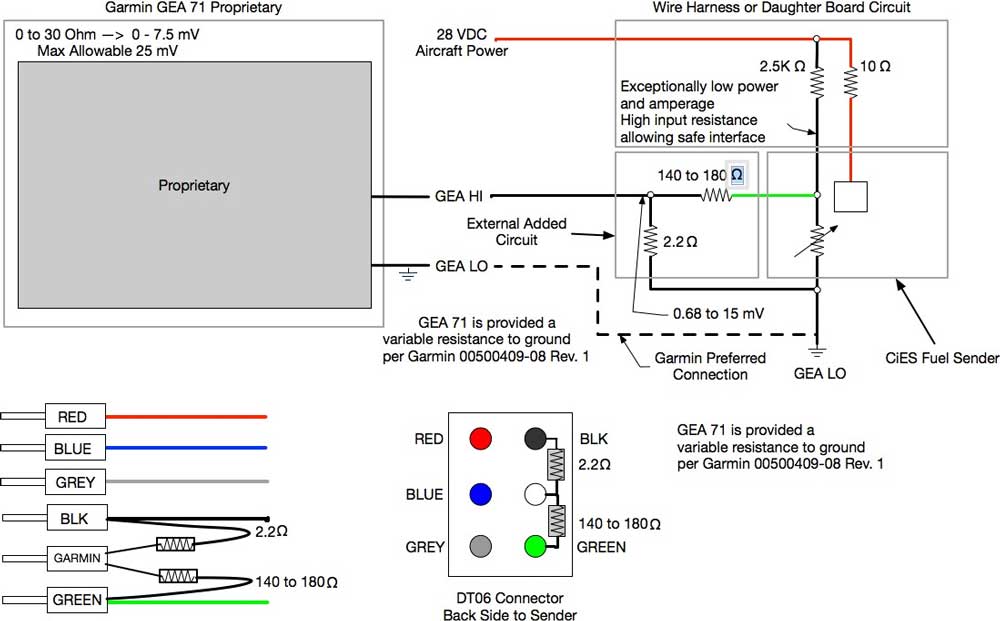

5.3.3 Garmin G1000 Interface - Analog

Mooney & Beechcraft ONLY

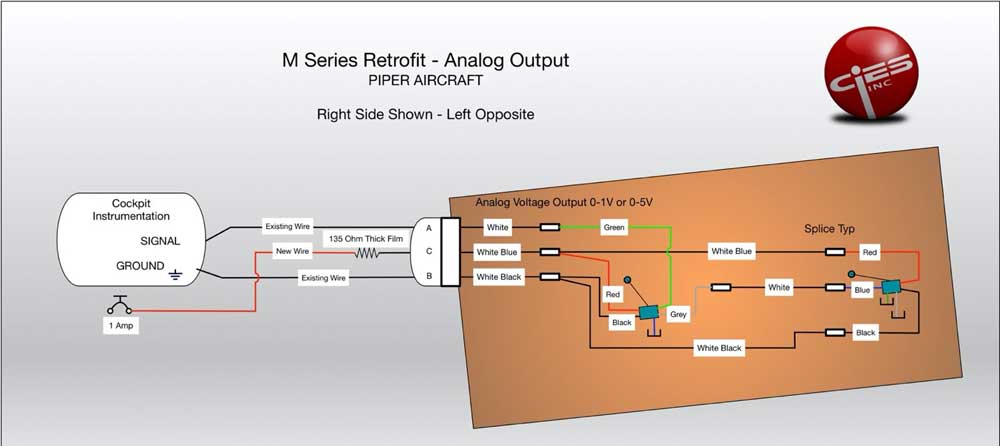

5.3.4 Analog Voltage Output

Piper Malibu ONLY

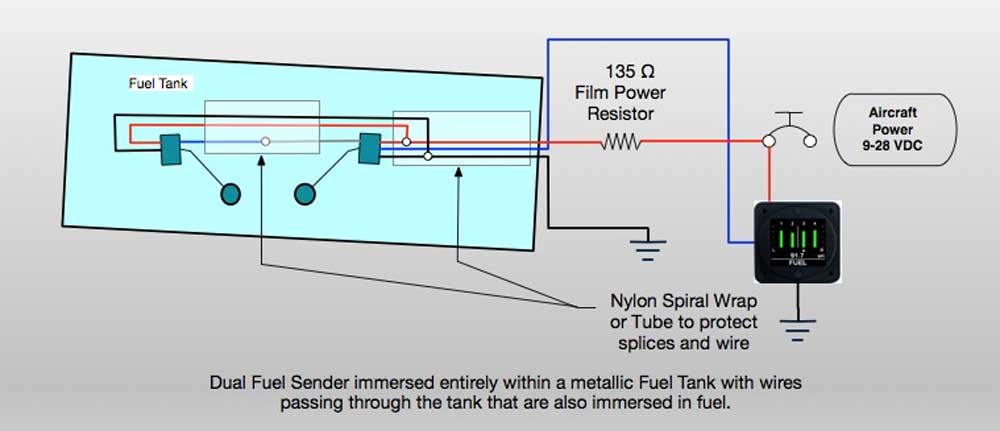

5.4 Immersed Fuel Senders

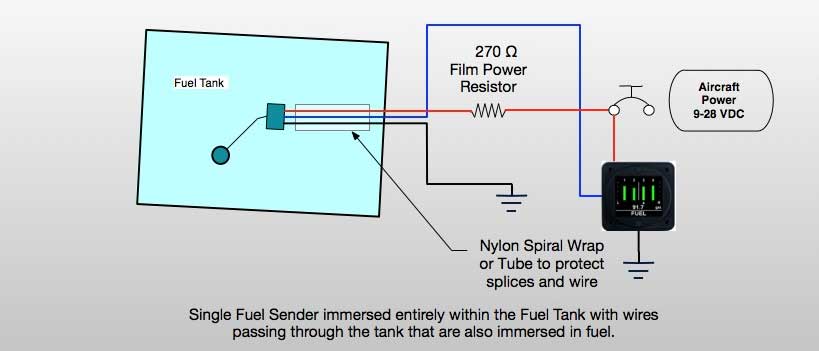

For installation where the sender is located entirely within the fuel tank (not attached to the outer tank or tank boundary) as on the Piper M Series, Cessna LC Series (TTX) or Cessna Twin Tip tank installations a current reducing resistor, and in the case of metallic aircraft a nylon tank conduit is required to insure that in the case of a wire breakage there is no potential for a spark of sufficient energy to initiate combustion if the tank were empty.

5.4.1 Immersed Pair of Fuel Senders

Precautions

5.4.2 Immersed Single Fuel Sender

Precautions

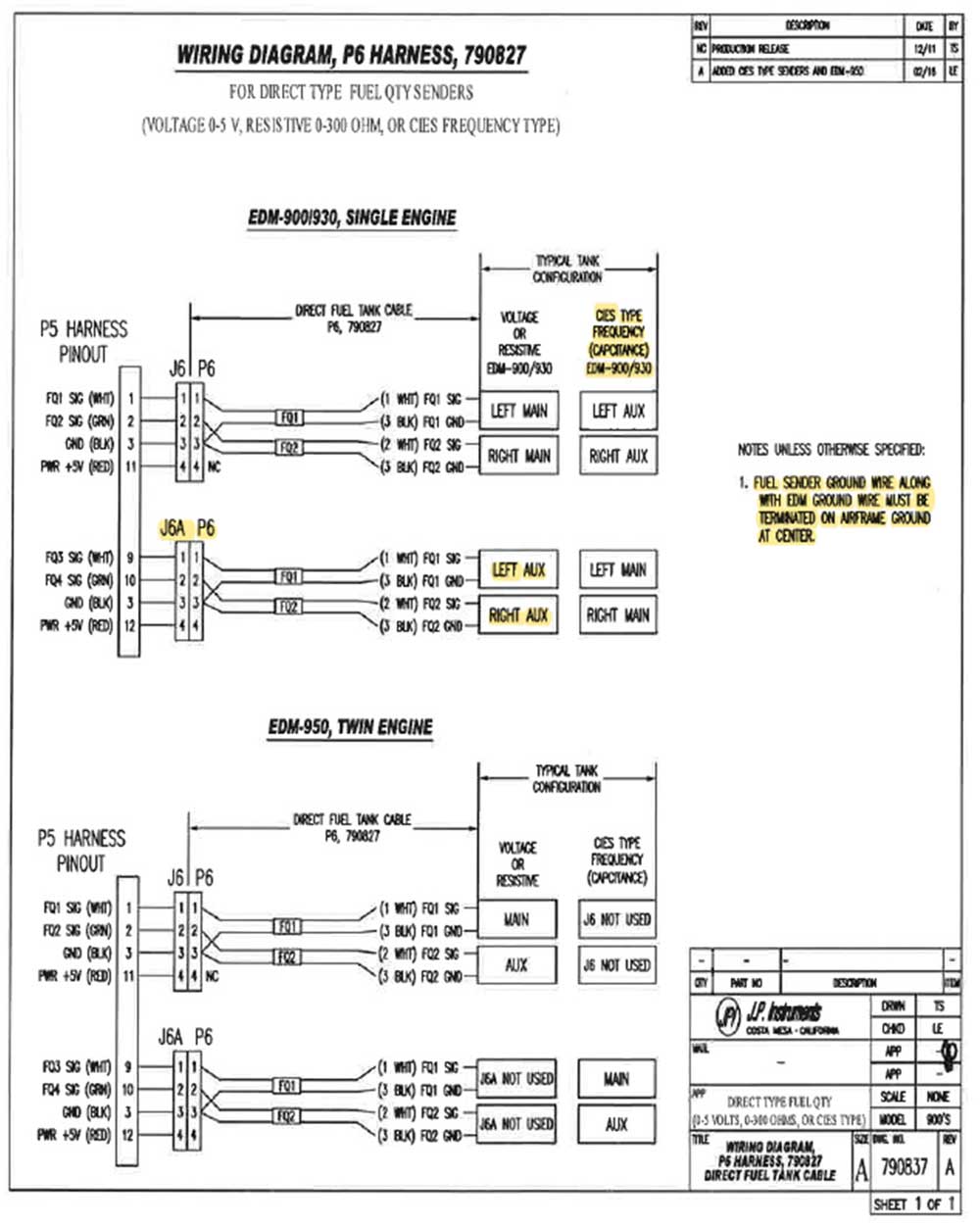

5.5 JPI 9XX Analog Input

For Existing JPI instruments Installed in the Aircraft (Not New or Converted)

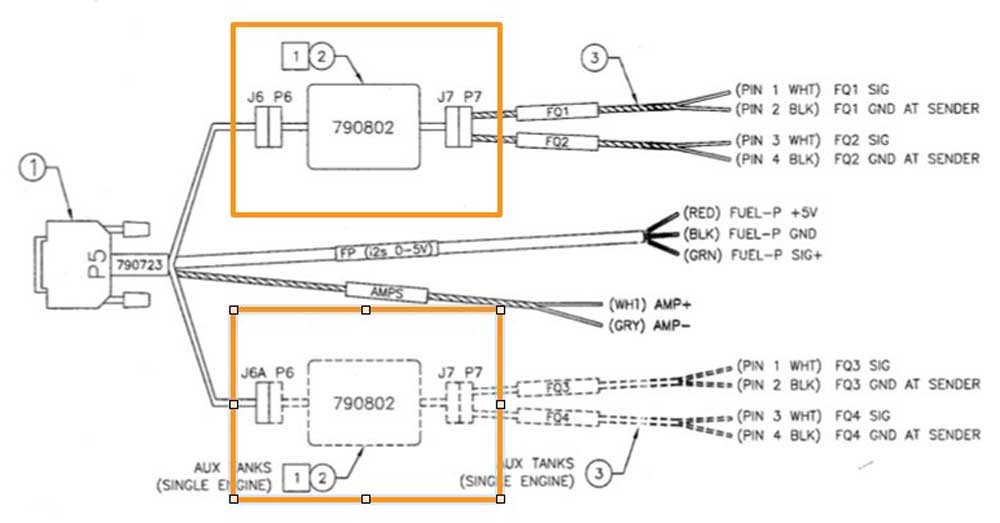

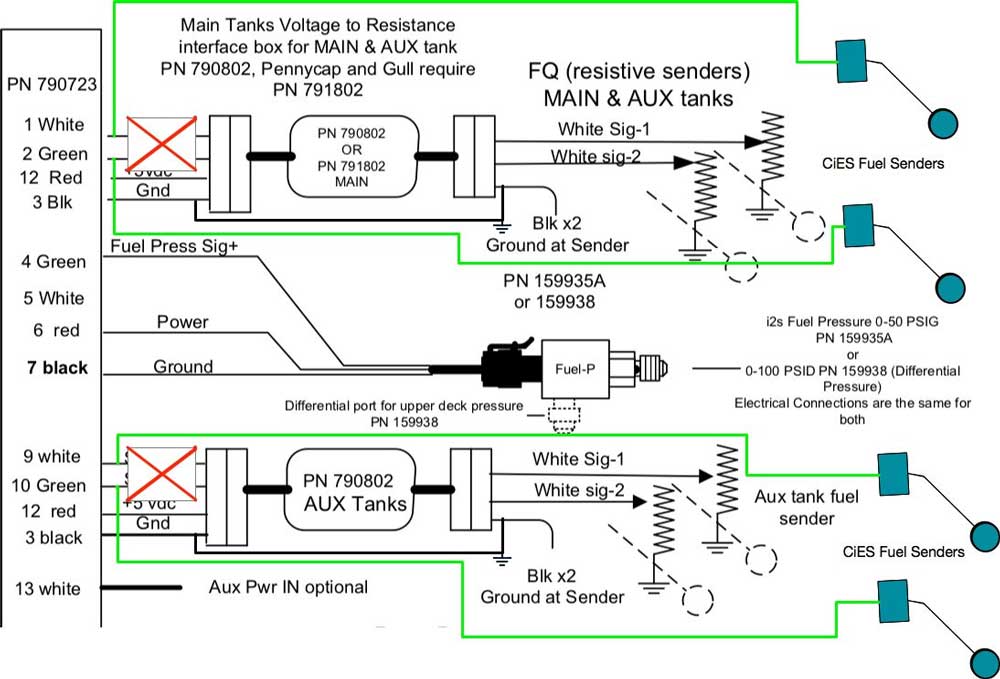

An existing JPI 9XX Series Display can be modified to allow an analog input from a CiES Fuel Sender. Despite the references to resistance JPI utilizes a variable voltage input for all analog fuel senders. JPI accomplishes this by utilizing a separate external voltage divider box or signal conditioner. This box accepts the resistive input and converts the signal to an analog 0 - 4.6 volt output for use by the JPI analyzer to determine fuel level. These boxes are highlighted below in Figure 5-15.

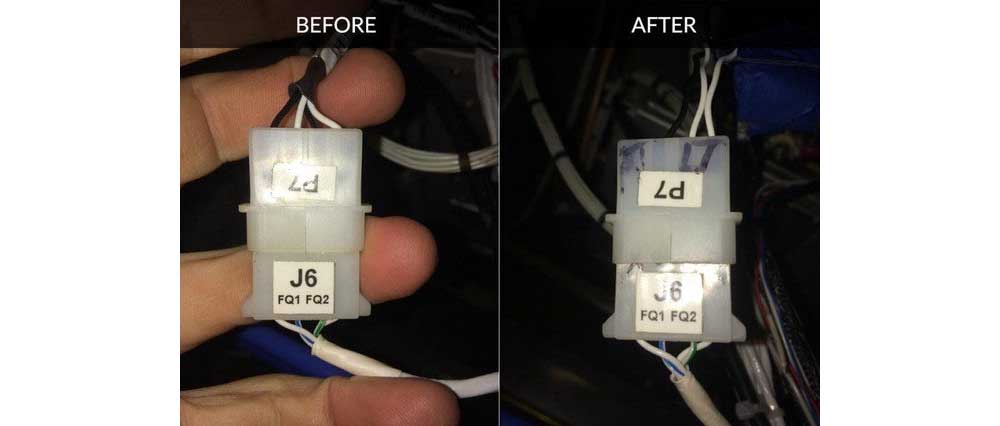

These signal conditioner boxes will need to be bypassed to allow the variable voltage output provided on the green wire of the CiES fuel sender to be used. Originally between J6 and P7 there is a JPI 790802 Signal Conditioner that converted the old resistance readings of the fuel senders to 0-4.6V for the JPI analyzer.

CiES senders outputting 0-4.6V, therefore the function of this Signal Conditioner is not needed and can be removed. However, you cannot just plug J6 and P7 together and have it work. You must rearrange the pins on P7 to match up J6.

Looking at J6 from left to right, pin 1 is 5vdc (white), pin 2 is Ground (Blue/white), pin 3 is Signal #1 (Green/White), and pin 4 is Signal #2 (White). The P7 must be reconfigured by moving male pins around to the following configuration left to right, pin 1 Disconnect, pin 2 (Black) Ground at sender, pin 3 Signal #1 (White), pin 4 Signal #2 (White). Wire colors may have changed.

Operation with this connection may be better on the aux tank interface. Contact JPI for assistance.

Schematically, the modification looks like Figure 5.15 with the CiES Fuel Sender Green wires connected to the JPI bypassing the signal conditioner.

5.6 JPI 9XX Digital Input

For New or Converted JPI instruments

6. Calibration

The following calibration procedures must be successfully completed for each tank on each aircraft after installing the CiES sending unit and prior to returning the aircraft to service.

6.1 Calibration Procedures

For multi-function displays and for dedicated fuel quantity indicators installed under a supplemental type certificate (STC), use the fuel quantity indicator calibration method that is called for by the applicable display system or indicator STC. The calibration procedure will typically be contained in the installation manual for the installed display device.

For displays and indicators provided as original equipment on an aircraft, use the calibration procedure contained in the aircraft maintenance manual.

6.2 Setting the Unusable Fuel Quantity

The calibration process at some point will call for the fuel loaded in the tank being calibrated to be equal to the unusable fuel quantity determined for that tank. That quantity is the unusable fuel quantity determined for that tank by test under § 23.959 or its predecessor regulations. The fuel quantity indication system will be calibrated to read “zero” or “empty” at this fuel quantity when the airplane is in a level flight attitude.

An acceptable method for setting the fuel quantity in the tank at the identified unusable fuel quantity is to drain the tank as fully as possible using the tank drains (this is usually 30 of 38 most effective with the airplane at the normal ground attitude), and then to add the unusable fuel quantity listed in the TCDS for that tank. Other methods may be used if accepted by the FAA inspector or designee that returns the airplane to service.

To achieve a FAA compliant Fuel Quantity indication in the cockpit as required by Part 91 and 135 operating rules. The fuel gauge is to read from full to empty for each tank.

Information, including FAA Approved Installation Manuals and FAA Pilot Handbooks that indicates that general aviation fuel quantity is only to be accurate at “Zero” is erroneous and a misstatement of the regulations.

These regulations require the pilot to accurately determine all usable fuel in the aircraft from EMPTY to FULL.

6.2.1 Where EMPTY is the FAA flight test determined and Type Certificate Data Sheet, or aircraft Maintenance Manual published aircraft “zero usable fuel quantity".

6.2.2 Where FULL is the published maximum fuel level indicated on the TCDS and fuel tank placard.

An FAA compliant fuel quantity system is to accurately read remaining Usable Fuel quantity per the aircraft FAA Approved Maintenance Manual requirements in any position between FULL and EMPTY values in level flight.

The FAA compliant display will drop consistently from FULL to EMPTY with the draining of the fuel tank in normal flight attitude in still air.

Calibration is achieved by the TSO and/or STC Instrumentation Requirements, listed in the specific FAA Approved Instrument Installation Manual or procedures listed in the Aircraft Maintenance Manual. Absent a listed procedure the following applies:

6.2.3 The aircraft will be jacked and leveled.

6.2.4 The aircraft will be emptied of fuel.

6.2.5 The applicable unusable fuel quantity listed in the TCDS will be added to the tank.

6.2.6 Confirm the cockpit display reads EMPTY and are within the tolerances established by the FAA Approved Aircraft Maintenance Manual if provided.

6.2.7 Any numerical value on the cockpit display will be confirmed and checked by adding that value of fuel to the tank in addition to the unusable fuel.

FULL fuel will be checked in a similar manner where the gauge will read Full.

For example: If the gauge has markings at 5, 10, 15 gallons - that amount of fuel will be added, and the cockpit display checked to ensure that gauge accuracy is maintained. (within the tolerances established by the FAA approved Aircraft Maintenance Manual.

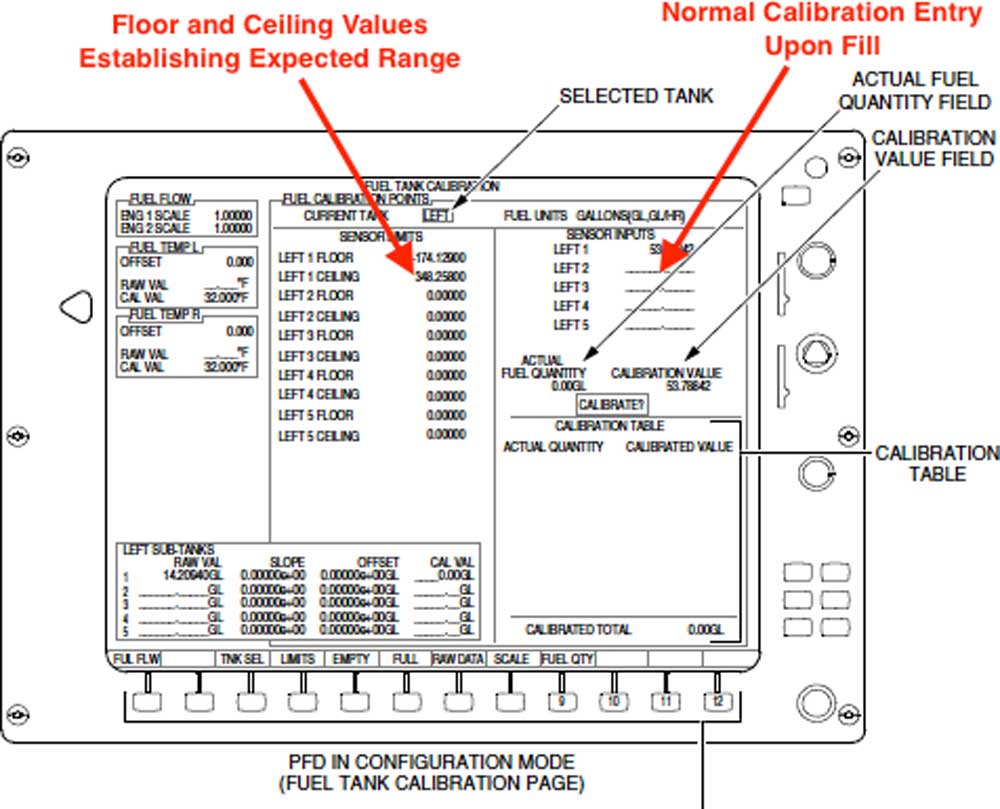

6.3 Garmin Factory G1000

If the indicated values shown on the Garmin Fuel Tank Calibration Page for CiES fuel sender inputs fall below the floor level at empty and or above the ceiling level at full, place the cursor over the values and adjust the floor and ceiling levels to be the input CiES sender value shown on the “Sensor Inputs” utilizing a value -10% shown for floor values and +10% for ceiling values.

6.4 Garmin G600 TXI & G500 TXI EIS

Ask your Garmin Dealer to contact CiES for instructions.

6.5 Garmin G3X

See Garmin G3X Installation Manual.

6.6 Cessna 208 (Caravan) Analog Gauge

See CiES CC-TR-2840-041 Calibration Procedure Cessna Caravan.

6.7 Rochester Gauges

First adjust the low gain fully counterclockwise prior to calibration.

6.7.1 Adjust FULL trim potentiometers to center travel.

6.7.2 Slowly adjust Empty trim potentiometer for each tank with zero fuel onboard until needle indicates zero gallons

6.7.3 Turn off power to the fuel gage.

6.7.4 Fill both tanks to full fuel level quantity.

6.7.5 Restore power to the fuel gauge.

6.7.6 Slowly adjust full trim potentiometers until needle indicates full for both tanks.

6.8 Requirements

While CiES Inc. fuel senders are FAA TSO C55a approved and has met a quality standard of 0.75% of tank capacity, that standard can only be met in the aircraft installation if and only if, the aircraft instrumentation, whether that instrumentation is TSO’d C55a or not, has the capability of accurately displaying at that level of sender accuracy. The AML STC SA02511SE prescribes the correct pairing of the CiES fuel sender with the appropriate FAA approved cockpit instrumentation and this information is also found in Section 2 of this manual.

A fuel quantity installation that meets the requirements of this manual must be able to effectively move between zero fuel and full providing an accurate representation of usable fuel in the cockpit.

Oscillations of fuel quantity +-4% of tank capacity in level flight & still air will require a replacement/refurbishment of the cockpit indication system to achieve an FAA compliant installation.

A fuel quantity installation that meets the requirements of this manual must be able to effectively meet the numerical, warning or cardinal indications present on the cockpit display or requirements of the POH or Service Bulletin. Absent an Aircraft Maintenance Manual tolerance indication, cockpit indicated values found in the POH and on the cockpit indication itself will fall within +1% and -3% of full tank capacity.

A low fuel annunciated warning may be incorporated that meets the requirements of the aircraft POH or FAR mandated operational requirements.

7. Troubleshooting

The simple design of the CIES fuel sender allows for only two common installation failures.

CiES senders are found on many new aircraft manufactured around the world. We build hundreds of sensors per month and our quality rating runs above 99% for all Aircraft OEMs.

CiES senders are thoroughly circuit-tested, burnt-in and retested before delivery – a sender issue is a very rare occurrence.

A simple bench test with a voltage source and a DMM (Digital Multimeter) having Hx setting will confirm proper operation.

Installed sender issues fall into three categories:

| ISSUE | CAUSE | WHAT TO CHECK | |

|---|---|---|---|

1 | No Indication Erratic Indication Partial Indication | You have no or insufficient power to the sender. | Check power directly at the sender – Do not assume that wire attachment to the CB panel or that a new wire run insures power at the sender. |

| Not reaching Full or Empty | Check that the ground is attached and there is little resistance to ground. | ||

2 | Fuel Quantity does not change with addition of fuel | The sender is physically restrained in the tank | Check that the float is not bound against the bottom of the tank, tank sealant, structure in the tank or wiring. |

| Not reaching Full or Empty | |||

3 | Display is erratic or does not appear | Improper display configuration or wrong input pin location | Consult with the display manufacturer for direction or see interface discussion in Section 6 of this manual. |

8. STC Instructions for Continued Airworthiness

G23.1 General

This section constitutes the required Instructions for Continued Airworthiness

G23.2 Format

This manual section forms the CiES CC284022 Series Instructions for Continued Airworthiness.

G23.3 Content

The contents of this manual are presented in the English language.

(a) Airplane maintenance manual or section

(1) Introduction

This system is a modification to the aircraft fuel quantity system. The system utilizes a

float or floats to detect the fuel level surface and transmits this data electronically to an

FAA Approved fuel quantity instrument in the cockpit. All the maintenance manual

aircraft requirements for fuel quantity accuracy requirements still apply.

CiES fuel quantity senders require aircraft power for operation while they are

physically identical in utilizing the existing mounting locations hardware and gaskets.

(Reference Section 3)

(2) Description

The fuel indication system measures the fuel in the tank by transmitting an angular

position of the of float or floats from a fixed position of the sender in the tank. These

floats ride on the surface of the fuel and in some instances the senders linearize that

angular output to integrate to the existing fuel quantity indication. The sensor measures

this angle in a non-electrical contact manner using a magnetic field detection.

The wiring location run in the installed aircraft for the additional power wire and the

ground wire attachment should be noted in the box below. The signal wire to the cockpit

is in the same wiring location as indicated in the aircraft wiring diagram. The additional

power wire should follow the same wiring run as the original signal wire in the aircraft. A

local ground can be utilized in metallic aircraft, otherwise the ground wire should follow

the same wiring run as the original fuel quantity signal wire.

(3) Operation

The sensor measures this angle in a nonelectrical contact manner using a magnetic field

detection. The magnetic field is located at the pivot point of the sender body. This

position may be transmitted by a 5 Volt square wave frequency signal or a linearized

analog voltage or current (resistive) output. (Reference Section 4.3)

(4) Servicing

The fuel level senders have no maintenance requirements or needs. The sensors

function and require no re-calibration for sensor output. If a sensor has failed or fails to

provide reliable or accurate fuel quantity output in the cockpit it needs to be replaced.

Reference the aircraft maintenance manual for sender location.

(b) Maintenance Instructions

(1) Scheduling

- On Condition

(2) Trouble Shooting

Each CiES fuel sender outputs a frequency including analog output senders (blue wire)

and operation of the individual sender can be determined if a frequency output exists

when power is applied to the sender with the ground wire attached. Power (Red),

Ground (Black), and Frequency (Blue) are the only wires necessary to determine fuel

sender operation.

- No Reading – check power to the sender unit, check blue signal wire for

frequency output Hz with power on the sender, if an analog wire is connected check

analog output, with power on the sender. Remove sender and inspect sender for

proper working condition and potential interference from a foreign object in the tank. - Incorrect Fuel Qty Level – check blue signal wire for frequency output Hz with

power on the sender, if an analog wire is connected check analog output, with power

on the sender. if there are multiple senders in the tank check each sender and check

that connecting the slave senders to the master sender (Typically the inboard sender)

changes the blue wire frequency output with power on all senders. Remove sender

and inspect sender for proper working condition and potential interference in the tank. - Unstable or Erratic Fuel Level Reading – ensure that aircraft power is supplied

to the sender and that the ground connection has less than 0.03 ohm resistance to

a known airframe ground like the aircraft engine mount or exhaust.

(3) Repair Procedure

If the fuel sender is found to either not produce a digital frequency Hz output or an analog

output, or the signal is erroneous, or erratic replace the sender and re-calibrate the

cockpit instrument.

(4) Procedural Instructions

Utilize the fuel quantity calibration procedures found in the aircraft FAA approved

maintenance manual or FAA approved aircraft instrumentation. The aircraft should be

leveled and jacked to prevent movement when fuel is added or subtracted. (Reference

Section 6)

(5) Other Instructions

No other requirements for service or maintenance.

G23.3 Airworthiness Limitations

- No Mandatory Replacement

- No Time Limitation

The Airworthiness Limitations section is FAA approved and specifies maintenance

required under Sections 43.16 and 91.403 of the Federal Aviation Regulations

unless an alternative program has been FAA approved” (required by regulation)

“There are no new (or additional) airworthiness limitations associated with the

equipment and/or installation”